Which of the Following Refer to Continuous Improvement of Business Processes

Business Process Improvement (BPI)

Each business owner meets with hundreds of business processes. Many of them are repeatable, like demo calls, marketing campaigns, reports on sales activities, etc. Any bottleneck in one repeatable process can cause millions of dollars in revenue.

Have you ever met with situations when:

- Complaint with the client is not resolved

- Production costs increase

- Sales manager decides to leave the company

When such situations happen you frequently lose time and money. You experience significant stress. Then, you do your best to renew the system's functioning. You want to prevent such situations in the future. This guide will provide you with valuable tools designed to improve your business operations. You'll learn how to improve any activity in your company. You'll go through the process improvement steps required for the desirable business efficiency.

Let's start with the simplest definition of business process improvement.

What Is Business Process Improvement?

Business process improvement (BPI) is an approach used to identify and evaluate inefficiencies within the organization. It redesigns existing business tasks, improving their effectiveness, enhances the workflows involved, and optimizes performance.

You have to classify the business activities into one of the categories:

- Operational – the most popular tasks repeating every day. Examples: opening accounts, reporting, manufacturing, logistics

- Management – focus on human resource development, budgeting, corporate governance

- Supporting – all other tasks not classified into the previous categories, like recruiting, accounting, tech support, and others.

Each task requires regular evaluation and correction. Then you can prevent undesirable inefficiencies. If you don't have such evaluations in place yet, you can install the process automation software. It will help to notify you of the defects along the way.

How to Improve Processes in Business: BPI Methods

Business process improvement requires various resources, proper management, and administration during implementation. Hence, to achieve the success you have to follow a certain methodology. It is a specific framework, designed for the company's guidance through business process improvement steps. Let's explore the popular BPI methodologies, which proved their effectiveness in various companies.

Six Sigma and Lean Thinking

Six Sigma is the BPI methodology, which history goes back to the 1980s. It was first implemented in Motorola. The idea of this approach is to provide a data-driven review helping to avoid any mistakes or inefficiencies in the current workflow. As a result, the system starts to work faster with fewer mistakes. At its foundation Six Sigma focused on manufacturing. But in recent years it developed into a more general approach, optimizing various activities within the company.

You have to understand that Six Sigma works with data to perform the required analytics. Therefore, it applies financial, project management, and data analysis tools. According to Six Sigma, the company can solve any problem within the business activity using the DMAIC framework.

DMAIC consists of several steps:

- Define the problem,

- Measure the current metrics related to the activity and the metrics after the improvement,

- Analyze the inconsistencies and defects that the job has,

- Improve

- Control to ensure that the entire system works efficiently.

One of the interesting modifications of the Six Sigma methodology is the Lean Thinking approach. This BPI methodology evaluates any job in terms of customer value. According to Lean Thinking, when some tasks do not bring value to the customer, they have to be eliminated. As a result, each activity brings a certain value, raising the company's productivity and customers' satisfaction.

Total Quality Management (TQM)

This business process improvement methodology is similar to Lean Thinking. But, it's more general in terms of effectiveness. Lean Thinking puts customer value at the center of a specific task, requiring optimization. On the contrary, TQM places the customer value at the center of the company's management and operation. Under the TQM structure, every department within the organization has to bring customers. The growth of customer satisfaction is the goal of the whole company. It's not the responsibility of management or customer success. Each employee has to make an impact on customer value.

Theory of Constraints (TOC)

TOC BPI methodology solves the inefficiency in the following way:

- Determines the constraint causing the bottleneck

- Improves this constraint until its negative effect disappears

The successful realization of this approach raises the company's productivity, streamlines the product flow, and optimizes the workflow, eliminating the inefficient bottlenecks.

In most cases TOC is based on the Five Focusing Steps methodology, which presumes:

- Identification of the bottleneck

- Elimination of this constraint

- Alignment of all other activities with the constraint's correction

- Realization of other possible actions to eliminate the bottleneck

- Movement to the new inefficiency

You have to remember that TOC is continuous. Once one constraint is eliminated, the other bottleneck comes in the TOC's focus.

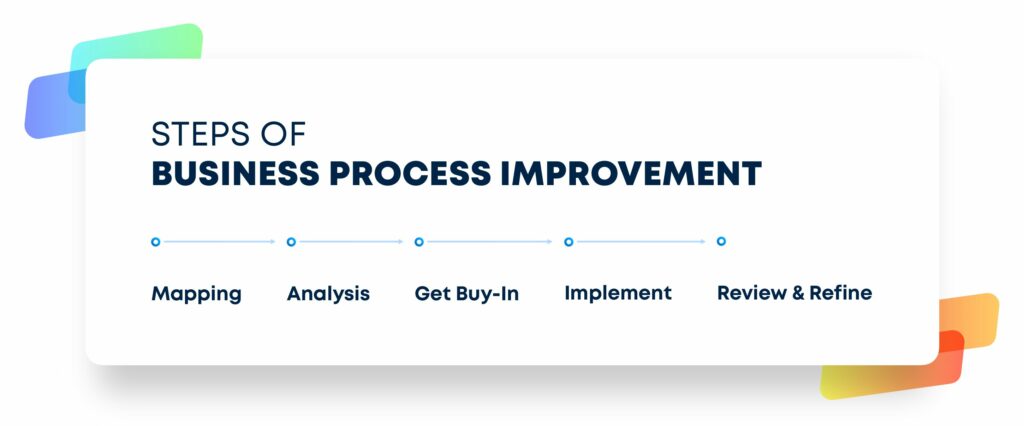

Business Process Improvement Steps

Now, when you have probably chosen the BPI methodology most suitable for the specifics of your business strategy, it's time to start the process improvement. But, what is the first step? Here, we present a list of the required steps one by one. In the end, you'll be fully equipped with all the instruments to realize your BPI strategy as soon as possible.

Step 1 – Mapping

The first step presumes the identification of the problem requiring elimination. At this point, you have to use mapping. It visualizes all the operations that you have within the organization and determines the one for optimization. You can perform the mapping in several ways. You can draw a flowchart manually or use the workflow automation software to do this for you. In the first scenario, it's quite likely that you'll miss some tasks or even part of the workflow. In the second one, you'll be able to see who is responsible for what within the organization and get actionable insights for optimization.

Step 2 – Analysis

Having mapped all the tasks within the organization, you can start the analysis of the pain points within the existing workflow. You have to ask responsible people and yourself some complicated questions, like:

- Does our company have jobs that are taking longer than required?

- In case we miss deadlines, what are the factors causing these situations?

- What are the main factors influencing the inefficiencies within the organization?

- Do we have activities critical for the financial state of the organization?

- Why do some of the tasks have a higher impact on the organization's effectiveness than the others?

Driving yourself through the set of these and similar questions will help to define the pain points for improvement.

Step 3 – Get Buy-In

At the next step, you have to display the existing problem before the senior management. As you understand, any change requires resources. It means you have to get approval for the action plan you are going to implement. When you present the situation to the senior manager, please show the following:

- The inefficient activity within the current workflow

- The impact of the existent constraint on the full cycle of the company's production

- The impact of constraint on customer value.

You have to make this clear not only to management and stakeholders but to the employees involved in these activities.

Step 4 – Implement

Once you have received approval from senior management and sufficient resources to start the improvement, it's time to realize desirable changes. If you want to succeed at this step, please follow these requirements:

- Start corrections at a small scale

- Test and make corrections

- Involve additional resources in case of necessity

- Implement the final changes across all the connected tasks.

Step 5 – Review and Refine

When you've implemented the change, it's time for the review. You have to monitor whether the change has been worked out correctly. Then investigate its impact on other activities within the company. In case any problems are verified you have to start the new cycle of BPI.

Wrap Up

To simplify the BPI in the future you have to continuously monitor the effectiveness of business processes within the company and react immediately to any inefficiency. This can be easily done with business automation software. Using such software you can gather analytics of the company's performance, create interactive reports, and get important insights on the workflow. As a result, you can optimize business processes on time and prevent any inefficiencies.

Source: https://fluix.io/help/business-process-improvement

0 Response to "Which of the Following Refer to Continuous Improvement of Business Processes"

Postar um comentário